The success of water-based paint collision repair relies on precise management of drying and curing times, influenced by environmental factors like temperature, humidity, and airflow. These eco-friendly paints, with their rapid application and unique chemistry, demand careful handling to avoid surface imperfections and prolonged curing. Technicians must balance these factors using appropriate drying agents and coatings for optimal aesthetics and performance in both car dent repair and auto frame repair.

In the realm of auto body repair, water-based paint collision repair has gained prominence due to its environmental friendliness and rapid drying times. However, this process is not without challenges. This article delves into the intricate complexities of water-based paint collision repair, focusing on three critical areas: drying and curing times, surface preparation, and color matching and finish quality. By understanding and tackling these challenges head-on, professionals can ensure optimal results in restoring vehicles to their pre-accident condition.

- Drying and Curing Times: A Delicate Balance

- – Understanding the chemistry behind water-based paints and their drying mechanisms

- – Challenges with varying environmental conditions and their impact on drying times

Drying and Curing Times: A Delicate Balance

The success of water-based paint collision repair relies heavily on achieving the right balance between drying and curing times. Water-based paints, known for their environmental friendliness and faster application, have distinct properties that require careful consideration during the repair process. Drying too quickly can lead to uneven finishes, while allowing too much time can result in extended downtime, impacting efficiency in auto frame repair and car dent repair operations.

This delicate balance is crucial in achieving a seamless car restoration. Professional technicians must account for environmental factors like temperature and humidity, choosing the appropriate drying agents and coatings to ensure the paint adheres properly to the vehicle’s surface during the curing process. Getting this timing right is essential for maintaining the integrity of the repair work and ensuring the final product meets high-quality standards in both aesthetic appeal and structural strength across all car dent repair and auto frame repair scenarios.

– Understanding the chemistry behind water-based paints and their drying mechanisms

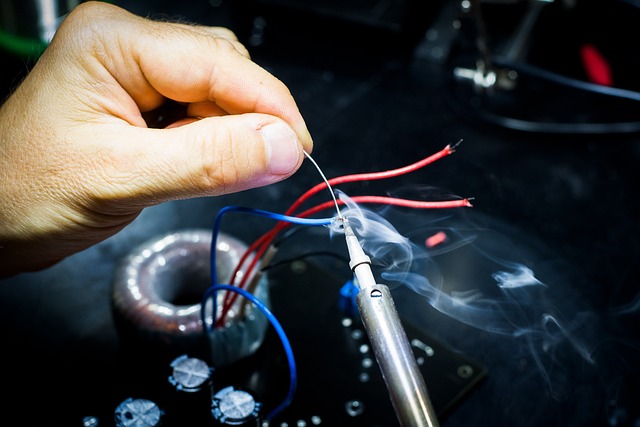

Water-based paints have gained significant popularity in the automotive industry for their environmental friendliness and faster drying times compared to traditional oil-based coatings. The chemistry behind these paints is complex, involving a mixture of pigments, resins, and various additives suspended in water. When applied to a vehicle body repair, these components undergo a series of chemical reactions upon exposure to air, leading to the formation of a robust, protective layer. Understanding this drying mechanism is crucial for ensuring optimal results in collision repair processes.

The drying process involves several stages. Initially, the water evaporates, leaving behind the solid components. This initial step is relatively quick due to the low viscosity of the paint and the presence of water-soluble resins that facilitate rapid solvent evaporation. As the paint dries further, cross-linking reactions occur between the resin and pigment particles, enhancing the paint’s durability and resistance to chipping or fading. Auto body painting professionals must consider these chemical interactions to address challenges such as uneven drying, surface imperfections, and long curing times, all of which can impact the final aesthetics and performance of water-based car paint repair jobs.

– Challenges with varying environmental conditions and their impact on drying times

The environmental conditions play a significant role in water-based paint collision repair processes, often posing unique challenges. Variables such as temperature, humidity, and airflow directly influence the drying time of the paint, which is critical to ensuring a smooth and durable finish. For instance, humid weather can prolong drying periods due to moisture in the air, potentially leading to longer waiting times for repairs to set properly. Conversely, extreme temperatures, both hot and cold, can accelerate or retard the drying process, respectively, adding another layer of complexity for auto detailing professionals.

These environmental factors are particularly pertinent during the automotive collision repair process where precise timing is crucial. In regions with fluctuating climates, technicians must adapt their approaches, potentially adjusting techniques or using specialized coatings to mitigate the effects of varying conditions. Effective management of these variables ensures not only the quality of the repairs but also streamlines the overall frame straightening and auto detailing workflow.

In conclusion, while water-based paint collision repair offers numerous advantages, it’s not without its challenges. Balancing drying and curing times, influenced by intricate chemical reactions and environmental variables, is crucial for achieving high-quality finishes. Understanding these complexities equips professionals with the knowledge to navigate potential hurdles, ensuring optimal results in every repair process.